In the intricate world of pharmaceuticals, where precision and control are paramount, the role of incubator analyzers extends beyond mere monitoring. These sophisticated instruments play a pivotal role in maintaining precise environmental conditions within incubators, ensuring the optimal growth and development of cell cultures, tissues, and microorganisms. This article delves into how incubator analyzers are unlocking the potential of pharmaceutical processes, ushering in a new era of productivity and efficiency. Tailored for the USA audience, let’s explore the transformative impact of incubator analyzers in the realm of pharmaceuticals.

Subheading 1: Introduction to Incubator Analyzers in Pharmaceuticals

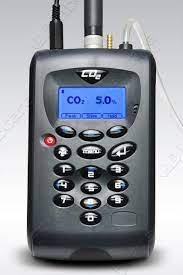

- Defining Incubator Analyzers: Incubator analyzers are advanced devices designed to monitor and control environmental parameters within pharmaceutical incubators, including temperature, humidity, and gas concentration.

- Critical Role in Pharmaceuticals: These analyzers play a critical role in pharmaceutical settings, ensuring that cell cultures, tissues, and microorganisms are cultivated in environments that support their growth and development.

- Precision and Accuracy: The precision and accuracy offered by incubator analyzers contribute to maintaining a stable and controlled environment, minimizing variations that could impact pharmaceutical processes.

Subheading 2: Optimizing Cell Culture and Tissue Engineering

- Temperature Control: Incubator analyzers regulate and monitor the temperature within pharmaceutical incubators, creating an environment conducive to the growth of cell cultures and tissues.

- Humidity Management: Precise humidity control is essential for cell culture and tissue engineering, and incubator analyzers play a key role in maintaining optimal humidity levels for these processes.

- Gas Concentration Monitoring: Some advanced analyzers monitor gas concentrations, ensuring that the cellular environment is enriched with the necessary gases to support specific pharmaceutical processes.

Subheading 3: Accelerating Microbial Fermentation Processes

- Ensuring Optimal Growth Conditions: Incubator analyzers contribute to microbial fermentation processes by ensuring optimal growth conditions for microorganisms involved in the production of pharmaceutical compounds.

- pH Regulation: Monitoring and regulating pH levels is crucial in fermentation processes, and incubator analyzers aid in maintaining the desired pH range for microbial cultures.

- Controlling Oxygen Levels: Some analyzers monitor and control oxygen levels, a critical factor in microbial fermentation, ensuring that microorganisms receive the required oxygen for efficient production.

Subheading 4: Advantages of Incubator Analyzers in Drug Development

- Enhanced Reproducibility: The precise control offered by incubator analyzers contributes to enhanced reproducibility in drug development processes, minimizing variability between experimental runs.

- Reduced Contamination Risks: By maintaining a controlled environment, incubator analyzers help reduce the risks of contamination, ensuring the purity and integrity of pharmaceutical products.

- Improved Efficiency in Research and Development: The efficiency of pharmaceutical research and development is bolstered as incubator analyzers provide researchers with a reliable and stable environment for their experiments.

Subheading 5: Technological Advancements in Incubator Analyzer Technology

- Sensor Technology: Advances in sensor technology have elevated the capabilities of incubator analyzers, allowing for more accurate and responsive monitoring of environmental conditions.

- Integration with Laboratory Systems: Modern incubator analyzers seamlessly integrate with laboratory systems, enabling automated adjustments based on real-time data and providing researchers with comprehensive insights.

- Data Logging and Connectivity: These analyzers often feature robust data logging capabilities and connectivity options, facilitating seamless communication between different laboratory devices and systems.

Subheading 6: Challenges and Solutions in Pharmaceutical Incubation

- Stringent Regulatory Requirements: Pharmaceutical processes are subject to stringent regulatory requirements, and incubator analyzers help meet these standards by providing accurate and verifiable data on environmental conditions.

- Adapting to Diverse Processes: The adaptability of incubator analyzers to diverse pharmaceutical processes, including various cell culture techniques and fermentation methods, ensures their relevance in different stages of drug development.

- Ensuring Data Integrity: Data integrity is crucial in pharmaceutical research, and incubator analyzers contribute to ensuring the integrity of environmental data, supporting the reproducibility of experiments.

Subheading 7: Future Trends in Incubator Analyzer Technology for Pharmaceuticals

- Artificial Intelligence Integration: Anticipate the integration of artificial intelligence into incubator analyzers, allowing for predictive analytics and enhanced adaptability to the specific needs of pharmaceutical processes.

- Remote Monitoring and Collaboration: Future incubator analyzers may support remote monitoring, enabling researchers to monitor and adjust environmental conditions for pharmaceutical processes from anywhere, fostering collaboration and flexibility.

Continuous Innovation for Pharmaceutical Productivity: Ongoing research and development initiatives aim to bring continuous innovation to incubator analyzer technology, with a focus on improving productivity, efficiency, and the overall success of pharmaceutical processes.