Folding cartons are the most commonly used types of product packaging. We probably have never paid much heed to these kind of cartons available on the shelves or the ones that reach us our parcels. However, there is a specialty in the various forms of folding cartons. The experts of folding carton manufacturers in Ahmedabad like Canpac use innovative technology to redefine the packaging solution. There can be different types of requirements for the client and as an established folding carton manufacturer, the team will be able to produce simple to complicated packaging that can fit in every kind of product.

Types of folding cartons

Broadly said, there are two types – the paperboard folding and the corrugated folding. The basic difference between them is that the former are made of single layered paperboard which is most popularly used for retail products while the corrugated cartons are made of two layers of cardboard paper which comes with a third inner layer which has air columns in between which gives it superior strength and makes the perfect choice for shipping.

Folding carton styles

The top folding cartons manufacturers can cater to different types of closing for the cartons and based on which there can be various styles such as –

Straight tuck box (ST)

This is the most common design and is widely used across plethora of industries. Even when you require custom printed folding cartons, the straight tuck box is the first choice. It is ideal for light and medium weight products, does not require any sort of assembling and can store items in the most compact manner.

Reverse tuck box (RT)

These are also similar to the first one except that it has closing panel which is on the back of the box and the other panel is attached on the front. They can be folded in opposite directions similar to ST. This is also perfect for light to medium with products and requires no assembling. You can store compact products and have slit locks for better closing.

Lock bottom box

They are also referred to as 1-2-3 button boxes. You can use them for custom printed folding cartons and can be specially designed to contain heavy items the bottom claps are so designed that it gives the entire structure a very sturdy quality. There is a tuck top panel with slit or friction locks on the top. It requires three-step assembly and can be used to store items in the most compact manner.

Trash button box

It is also referred to as an auto lock button and it is the perfect choice when you are looking for storing items which need extra support on the base. These folding carton boxes can be pre-glued at the bottom for extra strength. It comes with tuck top closure and does not require any assembling.

One-piece tuck top boxes

It’s very strong and durable sort of carton that comes with double sided walls. It has one opening on the top with closing flaps in the base and has a friction lock. It can be used for wide range of industries and it is a brilliant option for using as a display box. The double walls give it the added strength and come with very easy assembling.

Two piece boxes

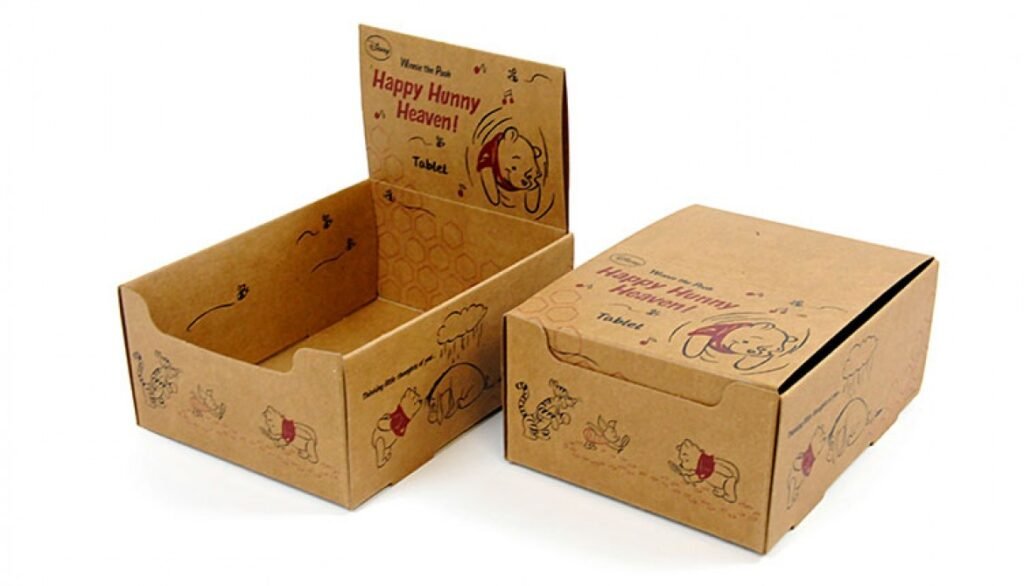

This is sometimes referred as kwikset tray and is one of the most elegant packing solutions. It can be seen for items like sweet assortments or luxury products and has a tray and a lid separately. They are both with double wall structures and can be very strong as well as durable to fit in a wide range of products. Understandably, they require easy assembly.

It has the top which is completely open and which is why is nicknamed as half box. It can be used for items like soap bars or other things that require visibility. You can store compact items and requires very simple assembly.

Nicknamed as pop up box, this has two basic purposes – display the items inside it and contain them. The lid of the carton can be open but also double as a shield. It can be used for selling grab and go items and requires very simple assembling.